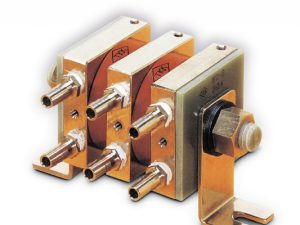

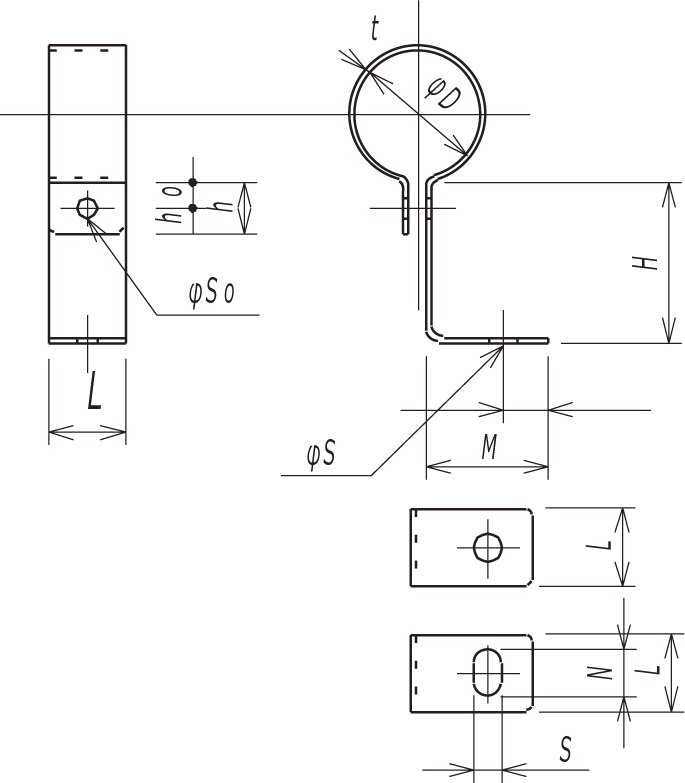

QL STANDARD TERMINAL CLIPS:

Material: Brass C2801 (Surface treatment nickel plating)

| Model | Resistor Type | Fixed Pitch for Terminal Attachment (mm) |

Dimensions (mm) | |||||||||||

| φD | L | H | h | ho | M | ℓ | φS | φSo | N | t | ||||

| QL-14 | ER10AS | ER20SP | 51 | 14 | 9 | 18 | 8 | 4 | 15 | 5 | 4.4 | 3.2 | – | 0.8 |

| ER20AS | ER30SP | 91 | ||||||||||||

| QL-20 (Long hole) |

ER30AS | ER50SP | 88 | 20 | 12 | 25 | 8 | 4 | 19 | 7 | 4.4 | 3.2 | 8 | 0.8 |

| ER50AS | ER100SP | 188 | ||||||||||||

| QL-25 | ER80AS | ER150SP | 229 | 25 | 21 | 32 | 9 | 4.5 | 22 | 8 | 5.4 | 4.2 | – | 1.0 |

| ER100AS | ER200SP | 279 | ||||||||||||

| QL-40 | ER150AS | ER300SP | 279 | 40 | 21 | 40 | 10 | 5 | 28 | 11 | 6.4 | 4.2 | – | 1.2 |

| QL-50 | ER270AS | ER500SP | 426 | 50 | 24 | 40 | 10 | 5 | 28 | 11 | 6.4 | 4.2 | – | 1.2 |

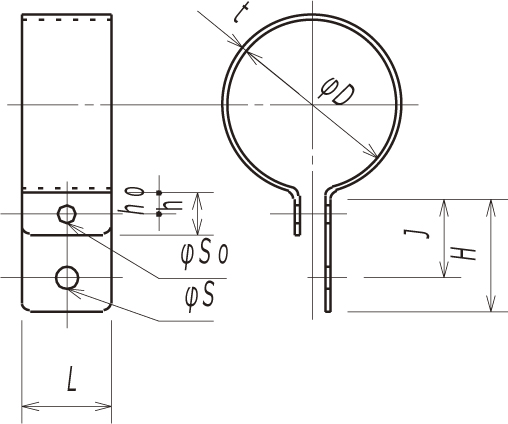

PQ STANDARD TERMINAL CLIPS:

Material: Brass C2801 (Surface treatment nickel plating)

| Model | Resistor Type | Fixed Pitch for Terminal Attachment (mm) |

Dimensions (mm) | |||||||||

| φD | L | H | h | ho | J | φS | φSo | t | ||||

| PQ-14 | ER10AS | ER20SP | 51 | 14 | 9 | 16 | 8 | 4 | 12 | 3.2 | 3.2 | 0.8 |

| ER20AS | ER30SP | 91 | ||||||||||

| PQ-20 | ER30AS | ER50SP | 88 | 20 | 12 | 20 | 8 | 4 | 14 | 4.2 | 3.2 | 0.8 |

| ER50AS | ER100SP | 188 | ||||||||||

| PQ-25 | ER80AS | ER150SP | 229 | 25 | 21 | 26 | 9 | 4.5 | 18.5 | 5.4 | 4.2 | 1.0 |

| ER100AS | ER200SP | 279 | ||||||||||

| PQ-40 | ER150AS | ER300SP | 279 | 40 | 21 | 28 | 10 | 5 | 20 | 5.2 | 4.2 | 1.2 |

| PQ-50 | ER270AS | ER500SP | 426 | 50 | 24 | 28 | 10 | 5 | 20 | 5.2 | 4.2 | 1.2 |

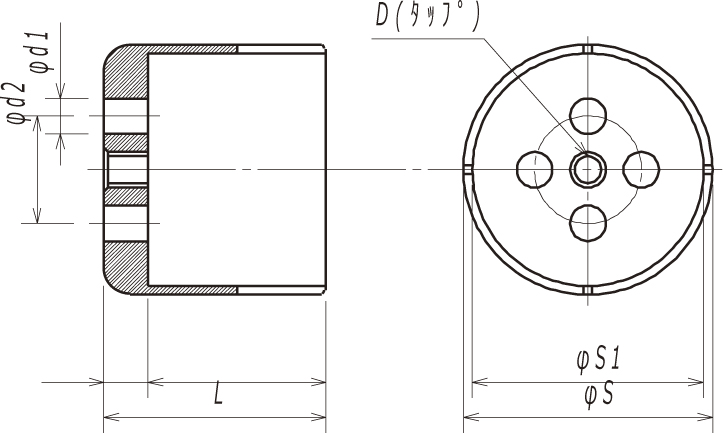

C STANDARD TERMINAL CAPS

Material: Brass C3604 Cadmireless 75ppm or less (Surface treatment nickel plating)

| Model | Resistor Type | Fixed Pitch for Terminal Attachment (mm) |

Dimensions (mm) | ||||||||

| L | ℓ1 | ℓ2 | D | d1 | d2 | φS | φS1 | ||||

| C-14 | ER10AS | ER20SP | 70 | 13 | 5 | 8 | M4 | 3 | 8 | 16 | 15 |

| ER20AS | ER30SP | 90 | |||||||||

| C-20B | ER30AS | ER50SP | 110 | 16 | 5 | 11 | M4 | 3 | 10 | 22 | 21 |

| C-20A | ER50AS | ER100SP | 210 | 18 | 5 | 13 | M4 | 3 | 10 | 22 | 21 |

| C-25 | ER80AS | ER150SP | 260 | 25 | 5 | 20 | M4 | 4 | 12 | 28 | 26 |

| ER100AS | ER200SP | 310 | |||||||||

| C-40 | ER150AS | ER300SP | 320 | 30 | 10 | 20 | M8 | 6 | 18 | 42 | 41 |

| C-50 | ER270AS | ER500SP | 470 | 33 | 10 | 20 | M8 | 8 | 24 | 52 | 51 |

Notes on the Standard Terminals

- Loose bracket can cause a spark or burn out. Make sure that the terminal is firmly secured.

When attaching your resistor to a terminal, tighten the screws at the specified torque. Overtightening can deform the terminal. - Make sure that your resistor is not wobbling when securing it to a terminal. Failure to do so can break the terminal or resistor due to torsion.

- Do not store any of these terminals in an environment with corrosive gases or excessive humidity. The terminals, which are made of brass, may cause stress corrosion cracking due to their material properties.

- If this happens, we will offer you terminal made of a different material.

- When using your resistor in a location exposed to excessive vibration, check the terminal.

- To transfer a power distribution board or something similar with your resistor secured to it, pack the distribution board while taking anti-vibration measures to prevent any excessive impact to the resistor.

- When securing C-type terminal, be careful that it is not placed under tensile stress.

- C-type standard terminal should be secured to a resistor by lead-free soldering (with melting point of 217℃). Therefore, make sure that the terminal temperature does not exceed 150℃.