Challenge

We continue to leverage the technologies that we have cultivated to enter new fields. We also take on challenges to develop advanced products instead of only manufacturing the same products all the time. These challenges include the development of environmentally friendly products, including products with high energy efficiency and recyclable products.

Diversity

We aim to develop an open corporate culture where employees are free to express their opinions.

By applying various perspectives and ways of thinking, we will develop the diversity of the company as a leading manufacturer of industrial furnaces, heating equipment and heating elements.

Reliability

We believe that we have earned a great deal of trust thanks to the experience and knowledge we have acquired over many years of devotion to the field of high-temperature applications. We are also striving to be a company that gains reliability by advancing technologies.

Industrial furnaces and heating equipment

Industrial furnaces and heating equipment, which are also referred as electric furnaces or combustion furnaces, are used for heating, sintering, dissolving and thermally treating ceramics, electronic components, metals, glass, powders and other materials at specific temperatures. We have an extensive track record in the design and manufacturing of industrial furnaces and heating equipment, etc.., for heat treatment. We also have advanced composite technologies as a comprehensive manufacturer of heating elements and refractories, which are necessary for industrial furnaces and heating equipment. With our track record and these technologies, we supply products ranging from small testing furnaces to large industrial furnaces for customers in every field.

Industrial FurnaceEREMA heating elements

Composed of high-purity silicon carbide (SiC), EREMA heating elements are the first silicon carbide heating elements marketed in Japan. Since we made them commercially available in 1927, we have been committed to research based on our wealth of experience, striving to improve their quality using our unique development technologies and other internal and external technologies. Now, we have been highly regarded for our production scale, which is the largest in the industry and our products, which are of the highest quality in the field.

EREMA Heating Elements

EREMA ceramic resistors

Since 1961, we have been involved in the manufacturing and sale of ceramic resistors, contributing to the improvement of technologies and performance in a wide range of fields including electric power, communications and healthcare. EREMA resistors are ceramic resistors sintered at a high temperature. They are therefore optimal for circuits which must be highly reliable under extreme conditions.

EREMA Ceramic ResistorsRecryte

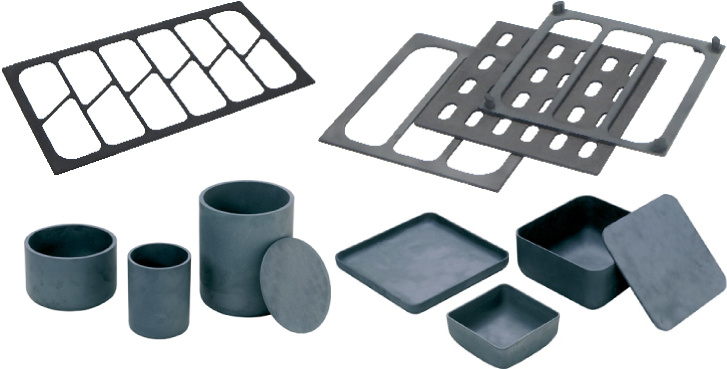

RECRYTE is the trade name of our SiC ceramic high-temperature materials. Our lineup includes recrystallized, reaction-sintered and pressure less-sintered materials designed to be used safely in high temperature environments.

Recryte

topics

The latest information is here